Engineering

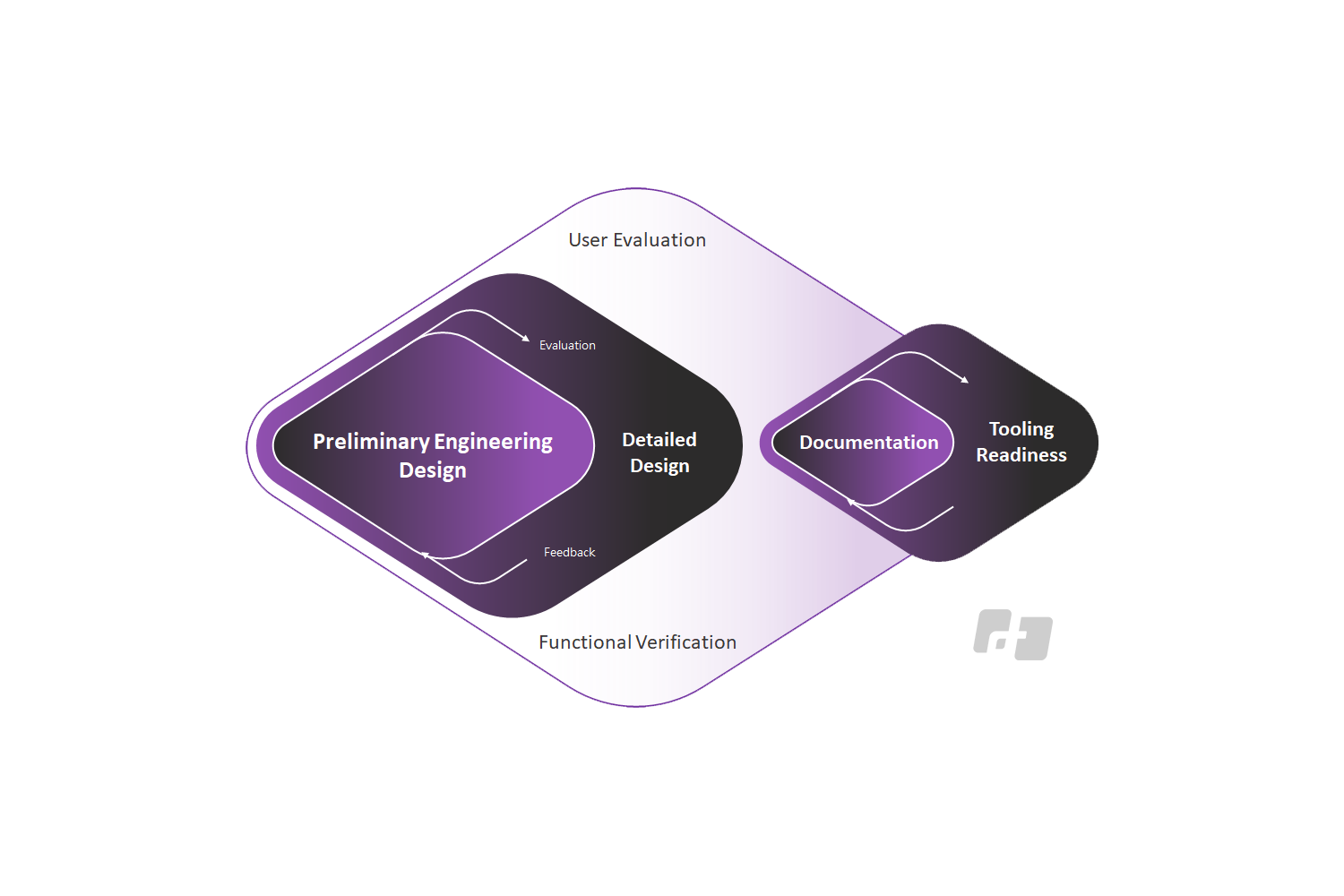

Functional Design, Development & Tooling Readiness

Our engineering group understands the symbiotic relationship between aesthetic design and functional implementation. With expertise in developing products from concept through production, DesignThink’s engineering team can see your product through to completion.

Creative problem solving

Physical study models and breadboards

3D CAD - Solidworks, Creo

Advanced surfacing- aesthetic and ergonomic design documentation

Top-down modeling

Structural FEA

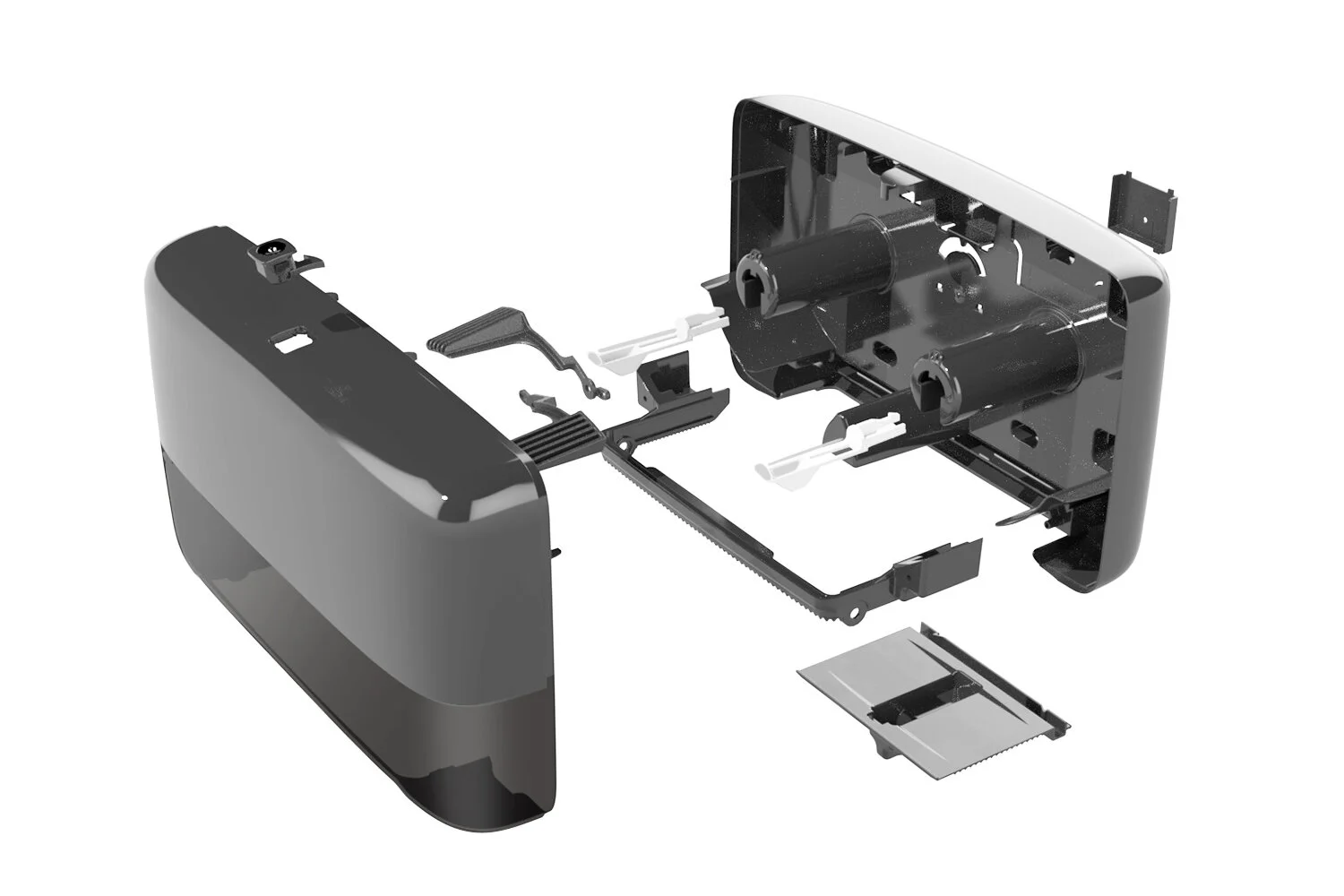

Mechanism design and analysis

Intellectual property (creation of new and circumnavigation of existing)

Rapid prototyping

Functional prototypes

Looks-like / works-like prototyping

Preliminary engineering development

Electromechanical systems

DFM / DFA

Performance characteristics

DFMEA

2D drawing packages

Tolerance analysis

Automation

Medical device engineering

Cleanroom compatibility

Biocompatibility

Design for sterilization

Interaction with manufacturing and tooling vendors (US / abroad)

On-site tooling and production support

Machine design

Assembly fixtures

Tooling release data package

First article inspections

Injection molding

Multi-shot molding

Insert molding

Extrusion

Sheet metal

Composites

Weldments

Castings

CNC machining